Project team: Ben Allen, Omar Ghazal, Marco Nicastro, Arthur Wong Massine Yallaoui / Photography + film: Ben Tynegate / Structural Engineer: Format CNC cutting: Hub Workshop / Installation: Sullivan & Co / Landscape Design: Daniel Bell Landskap

A Room In The Garden

A Room in the Garden is part garden folly, part “other space”. It is intended to relieve the congestion of the urban home and provide a space for family members to work, play, read, sleep or to enjoy a moment of peace and quiet. Packed with innovation, it is designed as both product and building. It is intended to be simple enough for self-build assembly and reassembly, coming as a flat pack kit of parts, fully fabricated on a CNC machine. It is ultra low VOC both in assembly and use and embraces the principals of circular design in that it can be fully demounted and re- erected. The project has been featured in The Observer, Dezeen, The Sunday Times, The Architect’s Journal, Detail, Dwell, Baunetz, decorpunk magazine, The Sunday Telegraph and the Times, Dezeen: 12 Garden Offices, Dezeen: 8 Home Offices . The project was also shortlisted in the Architect’s Journal Small Project Awards and the Offsite Awards.

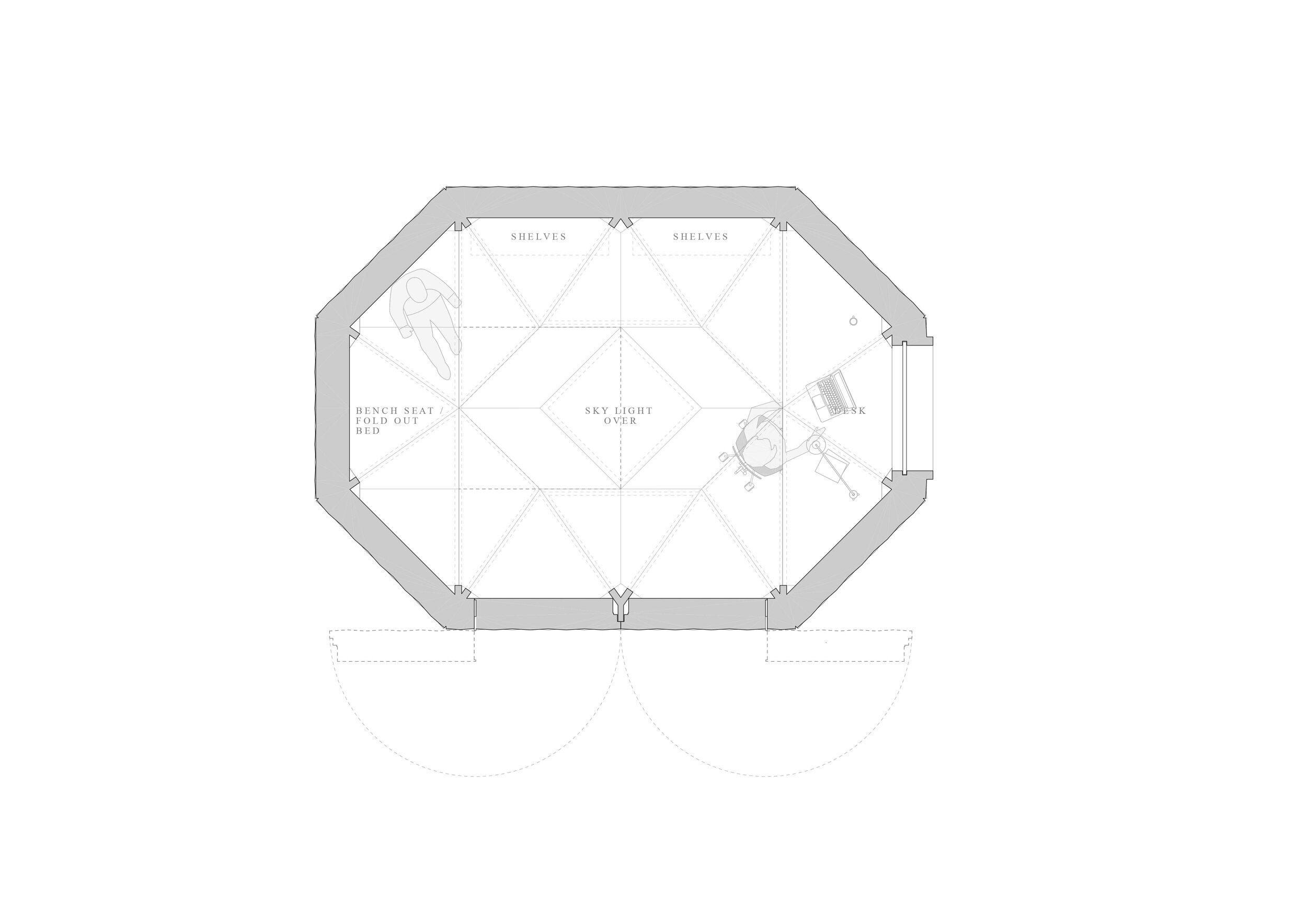

The geometry of the architecture is an interplay of changing geometric forms. The octagonal wall structure rises to form a hexagonal roof which then frames a square skylight. The main timber columns that support the walls converge to form a truss like structure that supports the roof. In so doing they give a heightened sense of verticality and therefore both a greater sense of space and an aesthetic reinforcement of the underlying geometry of the structure.

The intention was to design a structure that was both high quality yet affordable, quick and easy to assemble by a self builder and which could be taken down and reassembled. It was also important that it was low in volatile organic compounds (VOCs) both in its end use but also in its assembly. Each element is numbered and slots into the next. There is no on site cutting required and all of the screw and bolt fixing holes are predrilled. Internal and external linings are sheet material so there are no wet trades and therefore almost no dust and little noise created during the erection process.

The structure uses digital fabrication in the form of 2d flatbed CNC cutting technology. This was chosen as it is both affordable (compared to 3d or 5 axis CNC milling) and also a readily accessible technology, with workshops in many towns and most cities offering CNC cutting. The design of the structure pushes this technology to its limits, all elements are cut and notched to interlock. This has the advantage that it maximises the structural performance of the timber and avoids the need for measuring on site.

The building is built to modern UK building regulation standards, however the sprayed insulation means that it is airtight, ensuring that very little energy is required to heat it. The underfloor heating, lighting, rooflight and extract fan with humidistat can all be controlled remotely from a smart phone. This means that even during prolonged periods when not in use the temperature can be controlled and the space can be naturally or mechanically ventilated to ensure that remains dry, well ventilated and warm when needed.

With a team of 2 people, the main frame took 2 days to erect and the external linings and cladding took 4 days to install. The internal linings, underfloor heating, flooring and furniture took a further 4 days’ work, to a total of 20 person days. The only specialist required was the spray insulation contractor and an electrician.

Architecture, innovation, technology

We have striven to make A Room in the Garden, above all, a work of architecture. Architecturally it is designed to exude the playfulness of a folly, with the patterned green cladding is intended to partially and surreally camouflage the building in its natural surroundings. The interior is designed to adapt with the seasons: providing a sense of tactile warmth during the winter months, the large double doors enabling it to be opened to the garden in summer. The exposed timber structure which rises to the ceiling converging and framing the skylight, gives a central focal point and top light, ideal when seeking a place to read or for quiet contemplation.

In addition, the building features a number of innovations:

It uses digital fabrication to produce not simply and efficient structures or an essay in digital form but a work of architecture that is geometrically elaborate, spatially engaging and inspiring; It uses modern machine production techniques to make architecture that is both easy to assemble and accessible/affordable;

- Digital fabrication is used to put architects back at the centre of the building process, less reliant on contractors and fabricators and using our skill set to directly produce the construction components;

- It is a demonstration project for digital fabrication, a technology that is already upon us, in this case in the form of 2d CNC cutting. This flat-bed technology is readily available and uses a sustainable, inexpensive and readily available material – namely plywood and wood panel projects (such as MDF);

- Its assembly is a cleaner, healthier way of building that doesn’t risk health either during construction or in use. We believe that the current state of welfare for workers – in terms of VOC and dust levels on construction sites is archaic and needs to be urgently addressed;

- It is simple enough for a self-builder to assemble - this building is a prototype for a product that can be sold as is but also in a number of different affordable variants and configurations;

- It embraces the principals of circular design in that it can be dismantled either to be adapted or re-erected elsewhere. All of the materials can be easily disassembled, separated and recycled.

We passionately believe that architecture must be a synthesis of a conceptualised approach to aesthetics and the practical art of making. A Room in the Garden achieves that synthesis. In addition, we believe that architecture must continue to learn: in this project our client enthusiastically gave us the freedom to use this project as a research vehicle for number of significant avenues of investigation. In each of these areas we have attempted to push the boundaries and innovate, creating something beautiful on a very modest budget.